应用场景与百度百科/Brief Introduction:

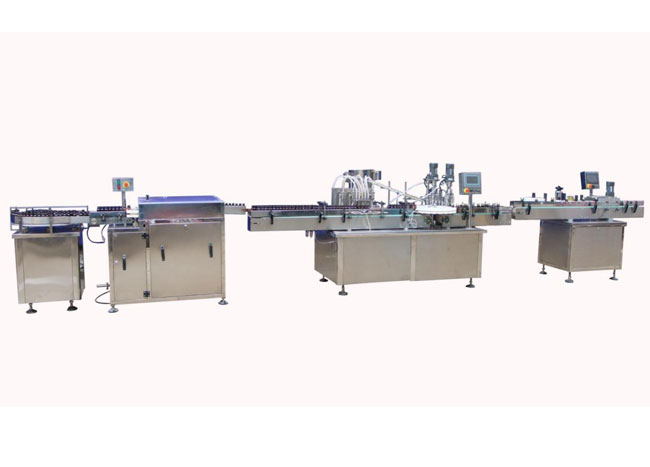

本种植方式线合适30ML之内内服液的装罐设备研发线种植线种植方式,由供瓶机、辊筒洗瓶机、垂直线式装罐设备研发线种植线轧(旋)盖机、柜式标贴机等的设备組成,可全系统自动实现理瓶、洗瓶、装罐设备研发线种植线、上盖、旋(轧)盖、标贴等繁琐流程。最主要用作药业有限公司、食品饮料、矿业的的很多液状体废料的装罐设备研发线种植线联合种植方式。本种植方式线充分合适GMP要。This production line is suitable for more than 30 ml of oral liquid filling production, by for bottle filling machine, roller bottle washing machine, straight-line rolling (spin) cover machine, vertical labeling machine and other equipment, can finish automatically unscramble bottle, bottle washing, filling and cover, cover and label (pad). Mainly used in pharmaceutical, food, chemical industry production of all kinds of liquid filling material of the linkage of. This production line in full compliance with GMP requirements.

亮点 /Characteristic:

◆外层材料为304装饰管材质,包装一小部分采316L装饰管材质,完全符合GMP规则。Outer material is 304 stainless steel,and the material of filling part is 316L stainless steel, it complies with GMP regulation ◆可适用于多要求研发。can be situable for several bottle specs.◆执行固定,空调噪声小,装灌精度 。Stable running,low noise,precise filling.◆破瓶率低,的成品符合标准率高,能效少。low bottle breakage ratio,high qualified product ratio,low energy consumption.◆整身产生线可手机单机管控和连锁加盟店管控。The whole line can single machine control or interlock control.工艺性能参数/Main Technical Parameters:

常用规格参数Filling Volume | 30-150ML |

装灌头数Productivity | 高转速4头 &n🏅bsp; 极﷽速8头 4 at low speed 💃 high speed 8 |

产生力 | 低挡30-50瓶/分 高速公路70-100瓶/分 30-50bottles/min 70-100bottles/min |

装罐定位精度Filling Precision | ≤±1% |

旋盖率Capping Rate | ≥99% |

外接电源Power Supply | 220V/50Hz |

马力Power Supply | 2.5kw |

工作线总长Dimension | 7500*1000*1700MM |

-

18217001818

18217001818

-

shnalong@aliyun.com

shnalong@aliyun.com

-

佛山纳庆机械产品制造产品受限集团

佛山纳庆机械产品制造产品受限集团

中文

中文  English

English